What is a Pearlescent Pigment?

Pearlescent pigments are coated mica platelets that provide color and exciting visual effects to various coatings, plastics, and printing ink. These luster pigments are transparent and reflect light because of their smooth surfaces. Light reflected from the platelets creates a sense of depth and a luster that varies with particle size—smaller particles impart a satin sheen. In comparison, larger particles create sparkle or glitter. Some pearlescent pigments are iridescent showing luminous colors that seem to change when seen from different angles. Although these pigments are non-metallic, they can give the paint a metallic look. Almost all pearlescent pigments are non-reactive and non-toxic.

The mica of pearlescent pigments is synthetic or natural, coated with titanium dioxide, iron oxide, or another metal oxide. Platelets of coated mica can vary in size, shape, and thickness. The degree of these characteristics and the thickness of the coating determine the color and appearance of the pigment. Additionally, the thickness and the coarseness of the particles determine the sparkle.

Rublev Colours Silver Pearlescent pigment is non-toxic and FDA-approved for use in personal care products and cosmetics.

The term "pearlescent pigment" derives from natural pearl and mother-of-pearl. These materials comprise layers that reflect some light while remaining translucent enough to allow light to pass further below the surface. Light is reflected back to reach the observer from several layers, including the top layer, creating a lustrous appearance of reflected light and depth.

Pearlescent, or nacreous pigments, come from either natural sources, such as fish scales, or synthetic sources (i.e., metal oxide coated micas, bismuth oxychloride, basic lead carbonate, lead arsenate, etc.).

While conventional metallic pigments are planar flakes of an opaque reflective material, pearlescent and other effect pigments use a multi-layer structure to produce reflection, refraction, and optical interference.

Pearlescent pigment grades include silver (white), interference colors (yellow, orange, red, violet, blue, green), earth tone colors (bronze, copper, russet), and gold colors (light gold and gold).

Mica is a natural mineral (muscovite) of low refractive index (RI) that is transparent in paint because it allows light transmission. When these thin platelets (about 500 nm) are coated with high refractive index metal oxides (ranging in thickness from 60 to 165 nm), they can reflect light. The face size of these particles ranges from 1 to 150 microns, and the thickness ranges from 0.1 to 3 microns.

What are Luster and Glitter?

Luster is a gentle sheen or soft glow resulting from a partly transparent substance with a partially reflective surface. The reflective property of minerals with vitreous luster is similar to that of glass. This is a very common type of luster and can occur in transparent or translucent minerals, such as quartz and calcite.

The glitter or sparkle effect of some pearlescent pigments is their ability to shine by reflection with many small flashes of brilliant light.

Rublev Colours Copper Pearlescent pigment is non-toxic and FDA-approved for use in personal care products and cosmetics.

How Pearlescent Pigments Work

White light is the name given to light that makes up all colors of the spectrum. When we see something as a blue pigment, we see the reflection of blue light. When we see something as a red pigment, we see the reflection of red light.

Mica platelets have a high level of transparency. White light will pass through the platelet—the titanium dioxide layer has a higher refraction index than the mica and the surrounding. Light is refracted and at the interfaces reflected in different angles. This phase shift creates so-called interference colors—the main characteristic of a pearlescent effect—. Iron oxide shows its typical color even in thin layers on a mica substrate.

Manipulating the metal oxide and its thickness allows formulators to fine-tune the reflection of specific wavelengths of light, creating custom and unique colors. Small changes in the platelet can have a significant impact on the pigment and colors that are visible.

What Are the Characteristics of Pearlescent Pigment?

In addition to the thickness and type of metal oxide, pearlescent pigments have different and defined characteristics that determine the color.

- Platelet Size—The size of the mica.

- Particle Size Distribution—A characteristic composition of fine and coarse particles leading to the PSD curve.

- Platelet Orientation—The direction the mica particles are facing.

- Pigment Concentration—The amount of pigment added to the base.

- Film Transparency—Transmission of unobstructed light through the film.

Rublev Colours Gold Pearlescent pigment is non-toxic and FDA-approved for use in personal care products and cosmetics.

What Is the Difference between Pearlescent and Iridescent?

Iridescence (also known as goniochromism) is the phenomenon of certain surfaces that gradually change color as the angle of view or illumination changes. Examples of iridescence include soap bubbles, feathers, butterfly wings, seashell nacre, and certain minerals. Structural coloration (microstructures that interfere with light) often creates it.

Pearlescence is a related effect where some or all of the reflected light is white, whereas iridescent effects produce only other colors. The term pearlescent describes specific paint finishes with iridescent effects, usually in the automotive industry.

How Are They Used in Paint?

Pearlescent pigments are used in the automotive industry to provide an alternative to metallics. These pigments provide a different luster and can create an unlimited variety of colors. These pigments are used in OEM as they allow for an endless spectrum of colors.

How Are They Used in Cosmetics?

Pearlescent pigments play an important role in the cosmetics industry. According to a Happi Magazine article, this market is set to grow by nearly 5% by 2022. These pigments add color, shimmer, sparkle, and glitter effects to cosmetics.

Synthetic mica is regularly used in the cosmetics industry due to its purity. Most pearlescent pigments in cosmetics use synthetic mica to create intense and bold colors while allowing for a superior skin feel and outstanding chroma.

Silver Pearlescent

Pearlescent pigments are thin, smooth, transparent platelets with high indices of refraction. The alignment of these particles in the end product and their particle size (which determines the luster effect—a reflectivity function) are also important characteristics. The larger the particle, the greater the luster and the better the orientation of the flake. While small particles don't orient as well, there are more edges to scatter white light, which results in higher opacity and a more "satiny" gloss.

Titanium white coated micas produce luster and give a sense of depth due to reflection, transmission, and further reflection from many layers. A luster impression is observed since the eye collects light reflected from platelets at different layers and, therefore, a sense of depth.

When white light falls on a multi-layer pigment, some is reflected on the metal oxide-coated surface. Reflection produces a phase shift of half a wavelength. The rest of the light passes through the outer layer, and some of the light is again reflected at the surface of the mica. It emerges from the pigment parallel to the first reflected component but with a different phase relationship which depends on how much further it travels through the metal oxide coated layer.

Another important consideration is the angle at which the light entered the layer and the wavelength of the light. If the two reflected components are in phase, they will appear bright, but colors out of phase will be suppressed by interference.

As shown in the table below, silver (white) grades are produced when mica is coated with titanium white. Varying the thickness of the titanium white coating will produce interference colors. As the thickness of the titanium white layer increases, the reflected color changes from silver (white) to yellow, red, blue, and green.

| Fraction | Size Distribution (µm) | Appearance |

|---|---|---|

|

Ultra-fine |

<15 |

Satin |

|

Fine |

5–25 |

Soft luster |

|

Standard |

10–60 |

Bright luster |

|

Sparkle |

10–100 |

Medium glisten |

|

Glitter |

20–200 |

Intense sparkle |

|

Super glitter |

70–700 |

Glitter effect |

Particle Size

Pearlescent pigments are offered in several highly controlled particle size distributions. The size will influence the luster, coverage, and appearance of coatings. The table below features a list of standard particle size distributions and their visual appearance.

| Coating Thickness (nm) | Reflected Color | Transmitted Color |

|---|---|---|

|

60 |

Silver |

Silver |

|

80 |

Yellow |

Blue |

|

100 |

Red |

Green |

|

120 |

Blue |

Yellow |

|

140 |

Green |

Red |

Luster generally increases as the particle size increases. The best appearance for pearlescent pigments is the optimum distribution of 10 to 60 microns.

This particle size distribution is tight enough to ensure a uniform oxide coating across all the particles, helping to boost the color intensity further. It also creates a D50 optimal for light reflection with minimal edge scattering. An example of this type of product would be Silver Pearlescent pigment. The larger distributions will appear glittery but provide the least coverage, while the small distributions will appear satin and have more coverage.

Particle size can be measured by several methods, including visual observation using a microscope, sieving, and laser light scattering, which is the most common approach. In this method, a pigment sample is dispersed in a liquid while a laser is trained on the liquid sample so that the platelets scatter the beam. Accurately positioned detectors measure the scattered light. Large particles scatter to a narrow angle, and small particles to a large angle. A computer calculates a size distribution based on the intensity of scattered light at different angles.

Laser light instruments provide several pieces of information. They can provide differential or cumulative size distributions, percent below a specified size, size below a specified percent (i.e., D50), and a distribution mode (the most populous size interval). Each piece describes a different attribute. No single piece can completely describe the size distribution or the effect it will produce in paint. Therefore, it is often necessary to use several data points for this purpose.

An important point about light scattering instruments is that they assume the measured particle is a sphere, not a platelet. Therefore, the size distribution is relative and not an absolute size measurement. In addition, different sizing instruments give different results. Large particles are emphasized because it takes thousands of tiny particles to equal the weight of one large particle.

White pearlescent color is produced from very thin titanium dioxide coatings, resulting in a mixture of colors being reflected. The reflective light is additive and combines back to form white light.

Pearlescent-type titanium dioxide coatings do not absorb light; they only reflect, refract, and transmit light, behaving according to the additive color scheme. This is different from the subtractive colors of pigments. With additive color, the primary colors of reflected light (red, green, and blue) add up to white light (see the table of illustrations below).

When blue and yellow pigments are mixed, they create green, but if a blue interference and yellow interference pearlescent pigment are combined, a white reflection is created. For this reason, it is not advised to mix interference colors other than for soft shading.

|

|

|

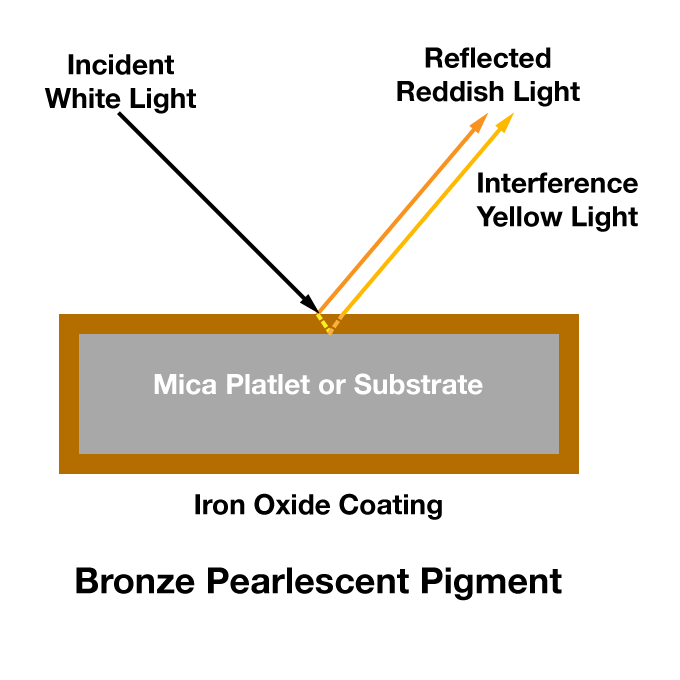

| Yellow light is reflected by interference with reddish light from the iron oxide coating to create bronze pearlescent pigment. | Orange light is reflected by interference with reddish light from the iron oxide coating to create copper pearlescent pigment. | Red light is reflected by interference with reddish light from the iron oxide coating to create a russet pearlescent pigment. |

The iron oxide coatings of colored pearlescent pigments exhibit the same interference properties as the titanium dioxide coatings, except the iron oxide contributes color of its own due to absorption by the iron oxide. Bronze colors correspond to the combination of a yellow absorption color due to the iron oxide and a yellow interference color due to the thickness of the iron oxide coating. Copper and russet colors are produced by similar effects (Figure 4).

Orientation

Maximum reflection and color travel are only achieved when the platelets are uniformly oriented parallel to the substrate. This is achieved primarily by film shrinkage and leveling of the coating while it is drying. It can also be affected by the size of the particles.

Film shrinkage is directly related to the total solids of the coating. Low-solids coatings shrink more than high-solids coatings, thereby improving the orientation and color travel. This is one of the primary reasons why high-solids coatings containing mica are a different color versus low-solid, waterborne paint, even though the pigmentation is the same. Better pigment dispersion, slow evaporating solvents used in the coating formulation, longer flashing time, or a ladder baking schedule will also improve the orientation of the pigments and achieve maximum luster. Figure 6 demonstrates the influence of two different solids formulations.

References

Sam Morell. Pearlescent Pigments–The Science of Optics. Online. Last Accessed November 20, 2020.

Frequently Asked Questions

How is pearlescent paint made?

Pearlescent paint is created by adding pearlescent pigments to a paint base. These pigments are usually made from mica coated with metallic oxides like titanium dioxide. When mixed into paint, they give it a unique, shimmering effect that changes under different lighting conditions.

Are mica-based pearlescent pigments edible or safe to eat?

Generally, mica-based pearlescent pigments are not edible unless specifically labeled as food-grade and approved for consumption. These food-grade pigments are processed and refined to be safe for use in food products. Always check the product labeling for safety and regulatory approvals.

Is pearl pigment powder the same as mica powder?

Not exactly. Pearl pigment powder is a type of mica powder that has been specifically treated to create a pearlescent effect. While all pearl pigment powders are mica-based, not all mica powders have a pearlescent finish; some may have matte or other finishes.

Is mica powder always pearlescent?

No, mica powder is not always pearlescent. Mica powders can come in various finishes, including matte, shimmer, and metallic. The pearlescent effect is achieved through specific treatments and coatings applied to the mica.

What is the most common pigment in paint?

The most common pigment in paint is titanium dioxide, primarily used in white paint. It provides excellent coverage and brightness, making it a staple in a wide range of paint formulations.

Is pearlescent paint expensive?

Pearlescent paint tends to be more expensive than standard paint due to the specialized pigments required to create the pearlescent effect. The cost can vary depending on the quality of the pigments and the paint base used.

Is investing in pearlescent paint worth it?

Whether pearlescent paint is worth the investment depends on the desired aesthetic effect and the project's budget. Pearlescent paints offer a unique and visually appealing finish that can add depth and character to a space or object.

Additional Tips for Using Pearlescent Paints and Pigments

-

When working with pearlescent paints, especially in automotive applications, ensure consistent application to achieve a uniform appearance.

-

Experiment with different lighting conditions to see how the pearlescent effects change and to find the desired look.

-

In cosmetic applications, always ensure that the pearlescent pigments used are specifically approved for skin contact and safe for use in personal care products.