Tempera is a method of painting with pigments dispersed in a binder that is miscible with water. Although the term is typically associated with egg yolk as the binder, it is also applied to paints made with casein, gum, or animal collagen (hide glue). The method was known from the classical world and was the principal medium used for panel painting and illuminated manuscripts in Byzantium, and Medieval and Early Renaissance Europe. The method was used in Europe for fine painting, mainly on wood panels, from the 12th century until the 15th, when it began to give way to oil painting.

This article examines the type of supports used today for tempera and the best practice of preparing them for tempera paint using a new ground, Tempera Ground, made by Natural Pigments. For information on preparing wood panels using traditional grounds (chalk or gesso mixed with animal collagen glue), please read Preparing Wood Panels for Painting and Preparing Collagen Glue.

Selecting a Support

What is a Support?

The term “support” refers to any material on which paint is applied. Canvas, wood, and paper are common painting supports, but the types of supports used for artwork are very extensive. Wooden panels, linen, and animal skins were among the first supports used for tempera painting. Engineered wood panels, such as plywood and hardboard, later became prominent in the twentieth century. Modern supports will most likely yield more advanced technology in composite materials. The search for the ideal support is perhaps a never-ending quest and is very much influenced by the types of materials available at the time.

Today’s most common supports for tempera painting include paper, illustration board, solid wood, plywood, and hardboard. Another modern support that may soon gain wide acceptance among tempera painters is an aluminum composite material (ACM).

Choosing a Support

Choose the support that best suits your needs. Sometimes, the support is an integral part of the painting itself. Painting traditions like religious icons may require solid wood panels with carved recesses. Others simply want a lightweight, flat surface for detailed brush strokes. The artist must determine what features are most important for the requirements at hand.

Tempera paint forms films of limited flexibility, whether egg, casein, or animal collagen. The best supports for these paints are rigid, such as solid wood, engineered wood, or composite materials.

Solid Wood

Solid wood is a term most commonly used to distinguish between ordinary lumber and engineered wood. Engineered wood products are manufactured by binding wood fibers or veneers with adhesives to form a composite material.

For more information about solid wood panels, please see Selecting Wood for Painting Panels.

Medium-density fiberboard (MDF) is less dense, strong, and hard than high-density fiberboard (HDF).

Fiberboard

The terms “hardboard” and “fiberboard” are often used interchangeably, even though they are different products. The significant difference between hardboards (i.e., Masonite) and fiberboards like medium-density fiberboard (MDF) and high-density fiberboard (HDF) is how they are manufactured.

Fiberboard panels are created through a dry process that relies on adhesives based on urea-formaldehyde or phenol-formaldehyde resins to bind the wood fibers together. High-density fiberboard (HDF) is superior to medium-density fiberboard (MDF) as it has significantly higher internal bond strength, greater density (more fibers per cubic volume), and is less susceptible to moisture damage. However, HDF is still prone to planar warping and fiber raising. Proper sealing or sizing and application of ground can mitigate this problem.

Medium-Density Fiberboard (MDF)

Medium-density fiberboard (MDF) is an engineered wood product made by breaking down hardwood or softwood chips and wood waste into wood fibers, often in a defibrator, combining it with wax and a resin binder and forming panels by applying high temperature and pressure. MDF is generally denser than plywood.

High-Density Fiberboard (HDF)

Also referred to as hardboard, a high-density fiberboard (HDF) is an engineered wood product. It’s made from wood fiber extracted from chips and pulped wood waste. HDF is similar but much harder and denser than particle board or MDF. It has a density greater than 50 pounds per cubic foot or 800 kilograms per cubic meter.

Hardboard is similar to medium-density fiberboard or MDF but is denser, stronger, and harder.

Hardboard

Hardboard is a composite panel manufactured primarily from inter-felted lignocellulosic fibers consolidated under heat and pressure. The wood fiber is extracted from chips and pulped wood waste. In the production process, the pulp is exploded under pressure. Heat and steam are applied to leave fine, fluffy brown fibers. These fibers are transformed into mats held together with lignum and other glues. Other materials may be added during manufacturing to improve specific properties, such as resistance to abrasion and moisture, and increase strength and durability. This product is also known under Isorel or Masonite brand names.

The North American industry standard is the American National Standard for Basic Hardboard (ANSI A135.4). It classifies hardboard by thickness and physical properties and includes five classes: Tempered, Standard, Service-Tempered, Service, and Industrialite.

Hardboard is similar to medium-density fiberboard but is denser, stronger, and harder because it is made of exploded wood fibers that have been highly compressed. Consequently, the density of the hardboard is 31 pounds or more per cubic foot (500 kg/m³) and is usually about 50–65 pounds per cubic foot (800–1040 kg/m³). It differs from fiberboard in that the bonding of the wood fibers requires no additional materials, although resin is often added. The hardboard variety is made without resin. The wet process, known as the Mason Method, leaves only one smooth side, while the dry-processed fiberboard is made smooth on one or both sides. Masonite is produced using the wet process only. High-density fiberboard is made with resin.

Tempered hardboards are impregnated with an oily or resinous substance, making them darker in color (untempered hardboards are usually a light brown color) and more resistant to moisture and mechanical damage (and therefore subsequent warping, raising of fibers, etc.) than untempered hardboard.

Masonite, one of the most commonly manufactured hardboards, began to be used for artistic purposes in the late 1920s.

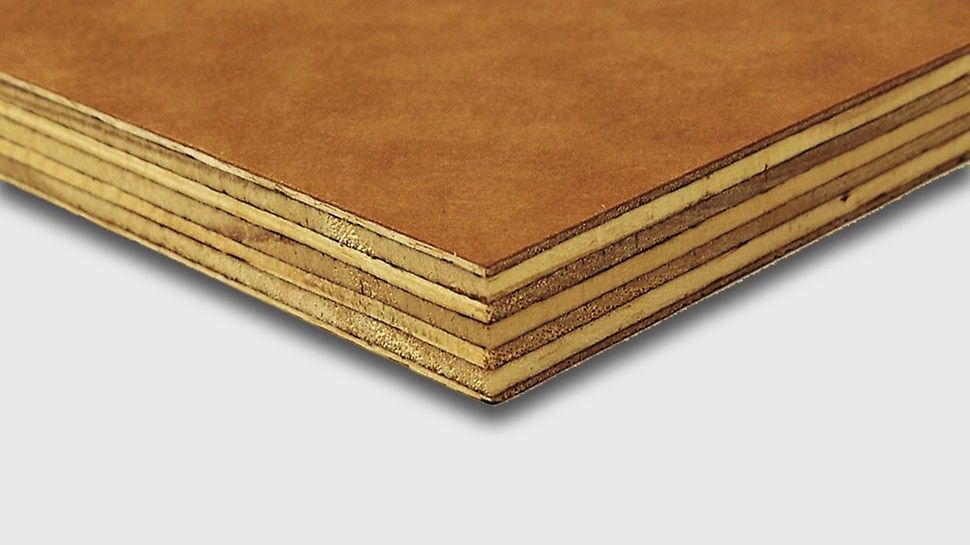

Birch plywood is a popular hardwood support for painting.

Plywood

Plywood is a sheet material manufactured from thin layers or “plies” of wood veneer that are glued together with adjacent layers, with their wood grain rotated up to 90 degrees to one another. It is an engineered wood from the family of manufactured boards, including medium-density fiberboard (MDF) and particleboard (chipboard).

All plywoods bind resin and wood fiber sheets (cellulose cells are long, strong, and thin) to form a composite material. This alternation of the grain is called cross-graining and has several significant benefits: it reduces the tendency of wood to split when nailed at the edges; it reduces expansion and shrinkage, providing improved dimensional stability; and it makes the panel’s strength consistent across all directions. There is usually an odd number of plies, so the sheet is balanced—this further helps reduce warping. Because plywood is bonded with grains running against one another and with an odd number of composite parts, it is tough to bend it perpendicular to the grain direction of the surface ply.

Standard quality plywoods only have their plies arranged at right angles to each other.

Thinner and lower quality plywood may only have their plies arranged at right angles to each other. However, by design, some better quality plywood products will have five plies in steps of 45 degrees (0, 45, 90, 135, and 180 degrees), giving strength in multiple axes.

Artists use plywood as a support for easel paintings to replace traditional canvas or cardboard. Ready-made artist boards for oil painting in three-layered plywood (3-ply) were produced and sold in New York as early as 1880. (Muller, 2013)

Medium Density Overlay or MDO Panel

Medium-density overlay panel, or MDO panel, is a plywood product with a weather-resistant resin overlay bonded to the wood by heat and pressure. The surface or veneer of MDO is very similar to MDF. One manufacturer of MDO panels (Roseburg DuraGardMDO) describes this overlay as “a high-quality paper that is saturated with phenolic resin solids and overlaid on our exterior-grade plywood panels.” The overlay, which has at least 27% resin content, resists water, weather, wear, and degradation. A similar product with a more rugged and smoother surface is called high-density overlay (HDO) plywood.

Initially developed for sign painting and concrete formwork, MDO is a paintable surface for other applications. Paint finishes on MDO are up to three times more durable than the same finish applied to ordinary plywood.

The paper veneer is overlaid on a plywood substrate with exterior grade (usually) phenolic adhesive. One or both faces can be surfaced with paper and are produced in 4 x 8-foot sheets from 3/8-inch to over 3 inches thick.

Support Induced Discoloration or SID

The water content of some water-based paints, mainly acrylic paints, may draw water-soluble impurities out of supports, such as cotton, linen, wood, or hardboard, as it dries into paint layers. As a result of these impurities, yellow or brown discoloration in the medium may occur over time. It will only be noticeable in areas that do not contain pigments, such as transparent glazes. It appears with all acrylic mediums currently made by fine art paint manufacturers.

The amount of discoloration will vary depending upon:

-

Quality of the acrylic medium.

-

The thickness of the medium application. Gel mediums are more susceptible to SID than fluid mediums. They are thicker, contain more water, and take longer to dry.

-

Substrate used. Different surfaces contain different colorants and contaminants.

Medium-density fiberboards (MDF) typically contain more water-soluble impurities than hardboards or plywood. To avoid support-induced discoloration (SID), see our recommendation below.

For more information about support-induced discoloration from wood, please read Avoiding Discoloration from Wood Panels.

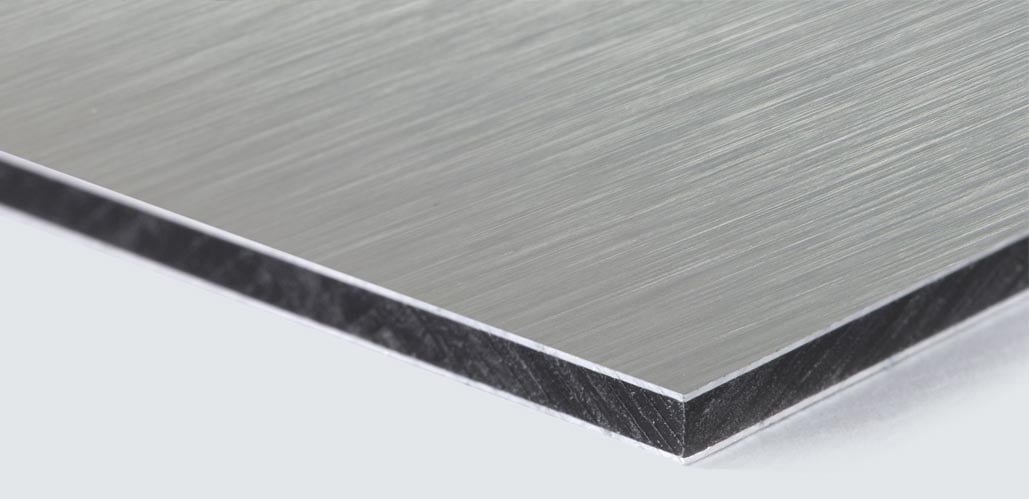

ACM is a panel of a plastic core sandwiched between two thin aluminum veneers.

ACM is a panel of a plastic core sandwiched between two thin aluminum veneers.

Aluminum Composite Material (ACM)

Aluminum composite material (ACM), or aluminum composite panel (ACP), is a flat panel consisting of two thin aluminum sheets bonded to a plastic core. The core can be solid or three-dimensional with corrugated or honeycomb configurations. ACM panels are frequently used for external cladding or facades of buildings, insulation, and signage. They are not responsive to environmental changes and do not warp when exposed to moisture.

Laminated Paper Boards and Museum Boards

Paper boards made from wood waste or pulp are sold under various trade names, including Upson Board and Beaver Board. Laminated paper boards should be thought of as temporary supports. They are highly acidic and have a weak physical structure, so they deteriorate quickly.

A Museum board is a high-quality laminated paper board made of 100% cotton rag mat board. Museum boards have between two and eight distinct layers. As the museum board lacks structural strength, it should be mounted on a wooden auxiliary brace or panel for increased rigidity.

Preparing the Support

Rublev Colours Tempera Ground is a very absorbent ground formulated for porous surfaces, such as hardboards, fiberboard, and non-porous surfaces. The advantage of hardboard and high-density fiberboard over solid wood and plywood is primarily due to the panel’s density and the fibers’ random orientation. This makes them less prone to warping and provides a smoother surface because there is no wood grain to show through the ground as it often does on plywood and solid wood surfaces.

Hardboard and Fiberboard

The procedure below is to prepare hardboard and fiberboard for painting. The exact process can also be used to prepare other engineered wood products, such as plywood and solid wood lumber:

-

Lightly scuff the face of the panel with very fine sandpaper (i.e., 320 grit or finer) to provide a slight tooth. Be careful not to roughen the surface and unevenly expose wood fibers. This can lead to irregular substrate swelling (particularly when water-based sizes, sealants, and primers/grounds are applied).

-

Degrease the surface with denatured or isopropyl alcohol before applying the size or primer/ground. Without this preparation, ground layers may not adhere to the smooth side of these supports because of surface residue, such as paraffin wax, that may remain during manufacturing.

-

Apply a sealant (or size) to both sides of the support to mitigate potential warping in the future. Possible sealants include Rublev Colours Fluid Medium, neutral pH PVA, acrylic polymers (i.e., high-quality acrylic dispersion mediums or gels), and varnishes (i.e., Conservar Isolating Varnish, MSA varnish, etc.). Bleached shellac and polyurethane coatings have also been used to effectively reduce the absorbency of the surface and seal the wood. Still, artists should take care not to apply these materials too thickly. Shellac and polyurethane are less than ideal materials regarding reversibility, brittleness, and aging characteristics.

-

Apply a second even coat of the sealant to both sides of the support. Allow to dry thoroughly.

Adhering Fabric or Paper to a Panel

It is unnecessary to adhere fabric to the panel before applying Rublev Colours Tempera Ground to a panel, as may be the case with traditional gesso or chalk grounds. However, this may be done, especially if a canvas texture is desired. To adhere fabric or paper to a panel, the following steps are recommended:

-

Apply one even coat of Rublev Colours Mounting Adhesive to the panel’s surface using a spatula or a brush.

-

Lightly wet the reverse of the canvas (the side that will be adhered to the panel) with water to promote better adhesion.

-

Use a brayer to eliminate air bubbles, working from the center outward to the edges.

-

If you keep excess fabric along the outer edges, fold them over and attach them to the panel’s backside (or affix them later).

-

Apply one coat of Rublev Colours Fluid Medium to the face of the canvas.

-

Once the canvas has dried, apply several coats of Rublev Colours Fluid Medium to the canvas and reverse side of the panel to prevent potential warping.

Auxiliary Support (Braces)

For large format panels and panels that are less than 3/4-inch thick, it is recommended to provide auxiliary support by attaching a brace or cradle by gluing strips of wood around the outside edge of the back of the panel using the following steps:

-

Obtain 1- by 2-inch wood strips (oak or maple are preferred) and cut them to match the outer dimensions of the support (overall size will depend on what type of join is used for the corners).

-

Butt and mitered tend to be the most common type of joins (consider using a 90-degree corner clamp when making mitered corners); however, lap joins are generally considered more structurally sound.

-

Make sure that the wooden boards are perfectly aligned and flush with the outer edges by laying them on the reverse of the panel before gluing them to the reverse (it can be helpful to mark the position with a pencil).

-

Use carpenter’s glue to adhere the wooden boards in place. While the glue is drying, clamp/weight the boards to avoid creating air bubbles.

-

Artists may construct horizontal and vertical crossbars for large-scale supports. However, crossbars should NOT be glued directly to the reverse of the panel; they should only be fixed to the outer boards of the cradle using glue or hardware.

Rublev Colours Tempera Ground is a polymer emulsion ground formulated for tempera painting with absorbent and sandable properties similar to traditional gesso or chalk grounds.

Applying Tempera Ground

Applying Rublev Colours Tempera Ground in multiple thin layers is best, gradually building up to the desired thickness. Single thick layers could crack upon drying. Follow this simple procedure to apply Tempera Ground to a prepared panel with a brush:

-

Apply Tempera Ground with a 1- to 2-inch broad flat brush. A stiff bristle or nylon brush is best to work the ground into the porous surface.

-

Apply the ground in thin, even coats using brush strokes in a single direction.

-

If desired, smooth the ground with a plastic knife or scraper.

-

Allow the coat to dry before applying the next one. Apply the next coat using brush strokes perpendicular to the layer below.

-

Apply as many coats as desired. It is recommended to allow the ground to cure for three days before painting.

Diluting

Brushing: This product may be diluted with up to 20% water for easy brush application.

Spraying: Dilute Rublev Colours Tempera Ground with Rublev Colours Fluid Medium. Begin at a 3:1 ratio of Rublev Colours Tempera Ground and Rublev Colours Fluid Medium) and test spray quality, as various spray equipment may require additional thinning. Further, you may need to reduce viscosity by adding up to 20% water.

Sanding

When sanding, follow these general guidelines:

-

Allow Rublev Colours Tempera Ground to dry completely before sanding. Cured films are easier to sand.

-

Start with coarser grit sandpapers, then finer grits until the desired smoothness is achieved.

-

Both wet and dry sandpapers may be used.

-

Wet sanding generates less airborne dust and produces a smoother surface than dry sanding.

-

Sanding to a glossy (polished) surface can reduce the mechanical adhesion of paint films. As always, test for your application.

-

Upon completion of sanding, use a damp, soft cloth to remove sanding dust particles from the surface. Failure to do so can cause poor adhesion.

Support Induced Discoloration (SID) Protection

To reduce discoloration of the ground and paint layer caused by Support Induced Discoloration (SID) when applying acrylic paint on supports that contain water-soluble impurities, such as canvas and wood panels, first, apply two coats of Rublev Colours Fluid Medium and allow to dry thoroughly. Then, apply the desired number of coats of Rublev Colours Tempera Ground.

References

Muller, Norman E. "An early example of a plywood support for painting". Journal of the American Institute for Conservation. American Institute for Conservation of Historic and Artistic Works. Retrieved 26 November 2013.

Disclaimer

The above information is based on research and testing done by Natural Pigments and is provided as a basis for understanding the potential uses of the products mentioned. Due to the numerous variables in methods, materials, and conditions of producing art, Natural Pigments cannot be sure the product will be right for you. Therefore, we urge product users to test each application to ensure all individual project requirements are met. While we believe the above information is accurate, WE MAKE NO EXPRESS OR IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, and we shall in no event be liable for any damages (indirect, consequential, or otherwise) that may occur as a result of a product application.