This tutorial is on preparing the grinding tools and dispersing pigments into the water to make your watercolor paint—a solution of gum arabic for watercolors. This technique can be used to prepare dispersions of pigment in water to be mixed with egg yolk for egg tempera, casein solution for casein paint, animal glue for distemper, and for use in fresco painting. The same technique can be used to disperse pigments in preparation for making pastels and pigment sticks.

Learn more about Making Waterborne Paint |

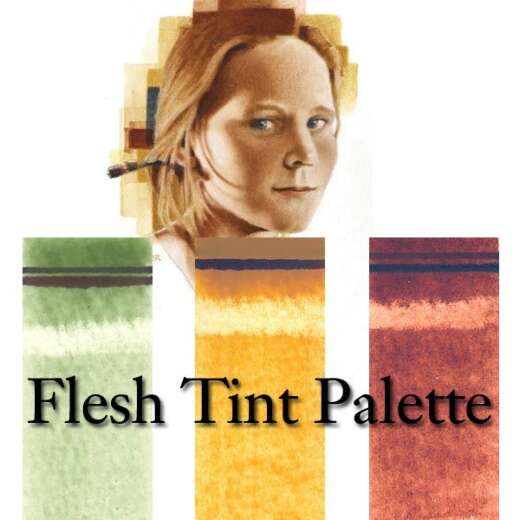

Why grind pigments to make your paint? Two primary reasons for doing so are to break down agglomerates of pigment particles and disperse pigments in the paint binder evenly. Most artists know the need to mix pigment with a binding medium smoothly. Still, few know how breaking agglomerations of pigment particles can also improve the color saturation of the paint. Fewer still know about the possibilities that grinding pigments afford for altering the visual appearance of paint.

Dispersing pigments into a paint binder with a muller on a flat surface helps to break down agglomerations or pigment particles that clump together from moisture and other weak binding forces. This helps make the final paint smoother and improves the opacity and color saturation of the paint. However, it is a common mistake to think that the force of grinding with a muller on a flat surface grinds pigment particles into smaller sizes. Greater mechanical force must be applied to do so. One way to do this is with a mortar and pestle. A pestle directs the entire force to a single point, whereas a muller applies the same force across its flat bottom surface. In addition, the pressure applied to the concave surface inside a mortar creates greater lateral forces to shear the particles into smaller ones. Grinding in a mortar can reduce the particle size of the pigment and, in some cases, alter its color substantially.

Not all pigments improve in color and appearance by being ground to a very fine powder and mixed with a binding medium. For example, the natural mineral malachite loses its color saturation the finer it is ground. On the other hand, some pigments, like cinnabar and lazurite (lapis lazuli), improve their chromaticity when grinding to the finest possible particle sizes.[1]

Many synthetic pigments available to artists today are prepared in extremely fine grades since they are made from precipitated chemical compounds. This makes for very uniform and small pigment particles that offer advantages in covering power and tinting strength. However, it also removes the exciting textures and intense chromaticity of natural pigments. At the very least, it does not allow the artist to control the pigment to its best potential in painting. Grinding pigments gives you the tools to overcome this limitation.

Rublev Colours pigments from Natural Pigments are made to careful specifications that do not destroy the pigment's best qualities and allow the artist to refine them for their use through elutriation or grinding. Many Rublev Colours pigments are raw materials that may require further processing by the artist to achieve specific desirable effects. Rublev Colours pigments can be used as they come out of the jar, or you may grind them to smaller particle sizes and separate them into different grades for special visual effects. As you become more aware of these possibilities, you may want to experiment, paying close attention to how the pigments look when mixed with your medium, whether it is oil, egg, acrylic, casein, or gum arabic.

Tools Needed to Make Your Own Watercolor Paint

The tools you need to disperse pigments and make paint are pretty simple; most are available locally. For convenience, Natural Pigments has put together a to help you get all the tools and materials you need to get started. Here are the tools you will need to get started:

| Item | Where To Find | |

|

Muller | Glass, stone, or ceramic muller large, small, and medium sizes are available Included in the |

|

Grinding surface | Plate glass at least a quarter-inch thick, marble, granite, or other smooth, non-porous flat surface. For best results, rub or sandblast the surface to give it a smooth but matte texture. See Preparing the Grinding Surface below. Included in the |

|

Spatula, palette, or putty knife | Spatula Included in the Also available from hardware stores and art supplies stores |

|

Silicon carbide | Also known by its tradename, Carborundum. Use 100 or 200 grit to prepare the surface. Included in the |

| Water | Distilled water is preferred Supermarkets or food stores |

|

|

Gloves | Latex, nitrile, or polyethylene gloves Available from pharmacies, drug stores, and medical supply stores |

|

Dust mask | NIOSH-approved dust mask or respirator Available from hardware stores |

|

Eye protection | Safety glasses or goggles Available from hardware stores |

|

Jars | |

CAUTION: Always wear a NIOSH-approved dust mask while grinding or working with powder pigment. Wear protective clothing and gloves while working with pigments in any form—dry or wet.

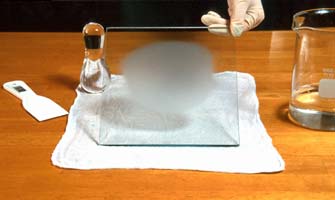

Preparing the Grinding Surface

The grinding surface must be roughened before it is useable for dispersing pigments. You will need about 15–20 minutes to prepare the surface for dispersing pigments. Here are the steps you should follow to prepare the surface:

Step 1

Place the surface on a firm support, such as a countertop or table. If you use glass as your grinding surface, you may find it helpful to put a white washcloth or a white kitchen towel beneath the glass to stabilize it while grinding.

Step 2

Pour a small amount of silicon carbide onto the surface. About 1/8 of a teaspoon will be acceptable to start with. Apply distilled water to the silicon carbide a drop at a time to make a stiff paste.

Step 3

Mix the water into the silicon carbide to make a paste the consistency of toothpaste.

Step 4

Place the muller onto the small pile of silicon carbide paste and move it in a circular motion, reaching the surface's edges. The corners of the grinding surface do not need to be roughened. Continue to grind in this motion for 5 to 10 minutes.

It will be necessary to remove accumulated silicon carbide paste from the sides of the muller using a scraper, palette, or putty knife. Periodically scrape the paste into a small heap at the center of the grinding surface to continue grinding. When you have completed grinding the surface, visually inspect it to see if it has been roughened by holding it up to a light at an angle. If the surface was smooth and shiny, to begin with, you should notice a matte appearance where you have been grinding.

To avoid contaminating your pigments, wash your tools with soap and water.

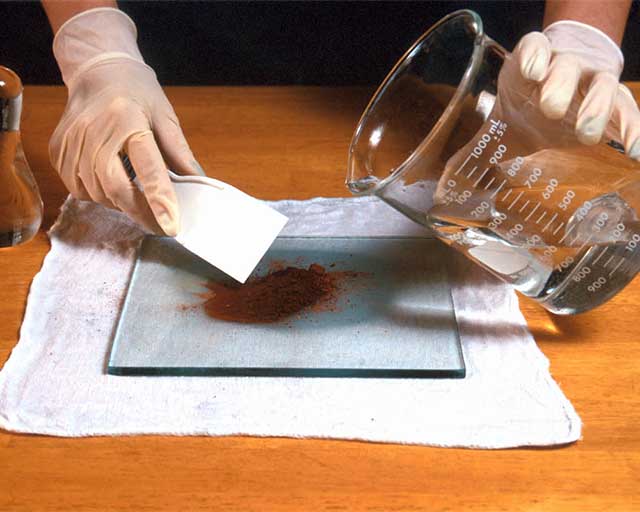

Dispersing Pigment into Water for Watercolor Paint

Now that the grinding surface has been prepared, you can begin dispersing pigments and making your paint. Let's disperse some pigment intended for use with water-based mediums, such as egg yolk (tempera), animal glue (distemper), gum arabic (watercolors), or fresco. It is best to disperse the pigment in distilled water. Tap water may contain many minerals and bacteria that may contaminate your paint.

Step 1

Place a small amount of pigment in a heap at the center of the prepared surface. Start by working with about 10 grams of pigments.

Step 2

Add a small amount of distilled water to the heap of dry pigment, a few drops at a time. Do not add too much water to start.

Step 3

Mix the water into the pigment with a spatula, palette, or putty knife. The correct amount of water is added when the pigment has the consistency of toothpaste. It is easier to judge the thickness of the paste once you begin grinding with the muller. Hence, it is better to begin grinding with a stiff paste than one with excess water.

Step 4

Holding the muller firmly with the heel of your hand and thumb up, slowly move the muller in a circular motion while keeping the pigment in the center of the surface. The pigment will slowly accumulate along the outside of the circle. Use the spatula to move the paste to the center of the grinding surface to continue grinding.

If the paste becomes too stiff, add more water, a few drops at a time. Do not worry if suddenly the pigment is thin and watery. Add more dry pigment to the mixture.

Periodically lift the muller from the grinding slab and remove any accumulated pigment from the sides of the muller using a spatula, putty, or palette knife.

Sometimes, suction will form between the muller and the grinding surface, making it difficult to move or lift the muller. Use the spatula as a lever to raise the edge of the muller. Then slide the muller horizontally off the grinding surface.

To prevent contaminating your subsequent pigment, clean your tools very well. If you have been grinding with water-based media, wash with warm water and soap. You may remove caked-on pigment and paint with any kitchen scouring powder, borax, or silicon carbide with the muller on the grinding surface. Follow this by washing with soap and warm water.

Ready to Use

The pigment paste is ready to accept your favorite water-based paint binder, such as egg yolk, hide glue, casein, or any other binder—even acrylics.

When Making Watercolor Paint

Instead of grinding powder pigment in water, grind pigment directly into a watercolor medium. This saves the step of later adding the watercolor medium to the pigment paste. The pigment paste with the watercolor medium can be stored in pans and tubes.

Shop Now for